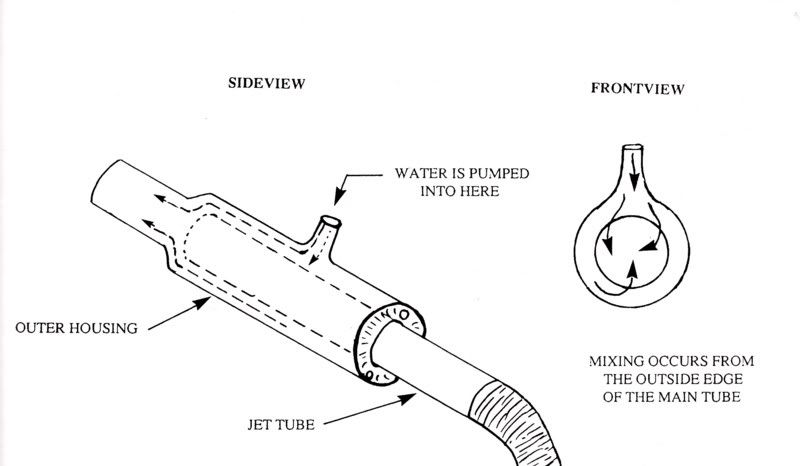

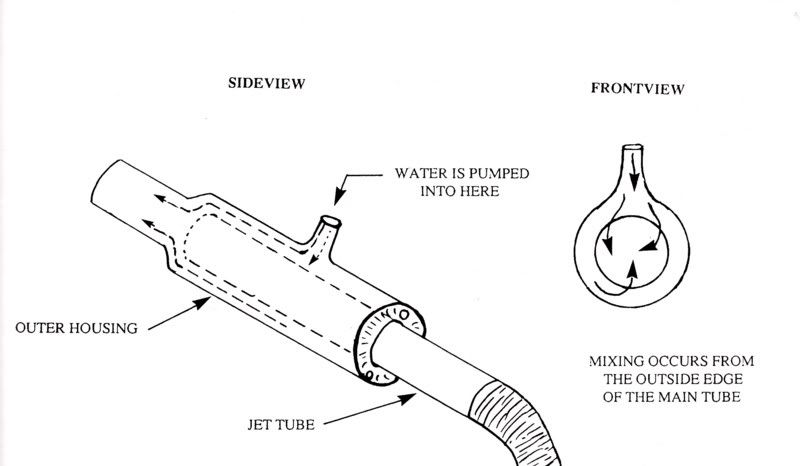

Hi guys, Here is a diagram of an infinity jet.

The picture is self explanatory......the water from the pump pressure hose enters the outer jacket incasing the whole suction hose power jet end & the water pressure is forced & directed out the end in the direction of the arrows. This causes the venture suction at the suction hose end to be of a uniform & equal amount over the whole exit end of the suction hose where as with a side entry pressure hose in to a power jet the water pressure entering at the angle to the main power jet tube is going to deflect off the side of the power jet & isnt blasting down the power jet tube in the centre, & in theory not being totaly efficient due to friction loss etc.

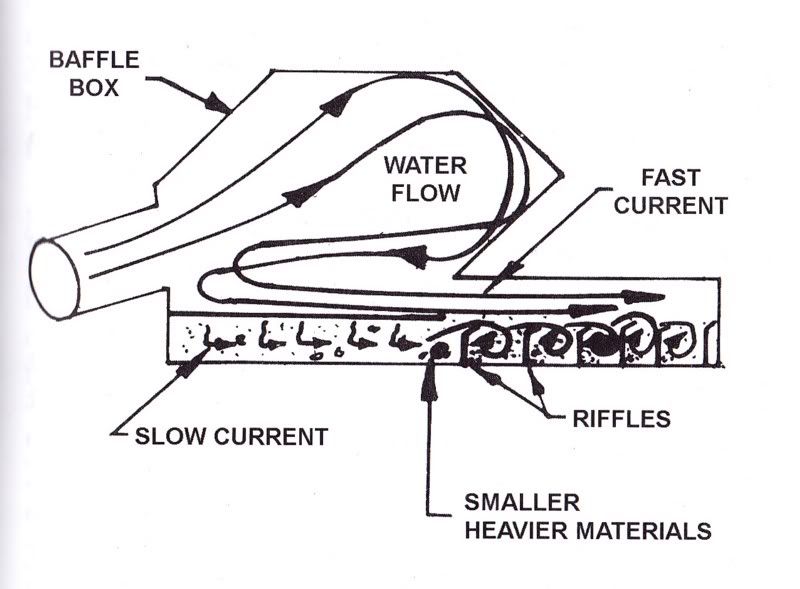

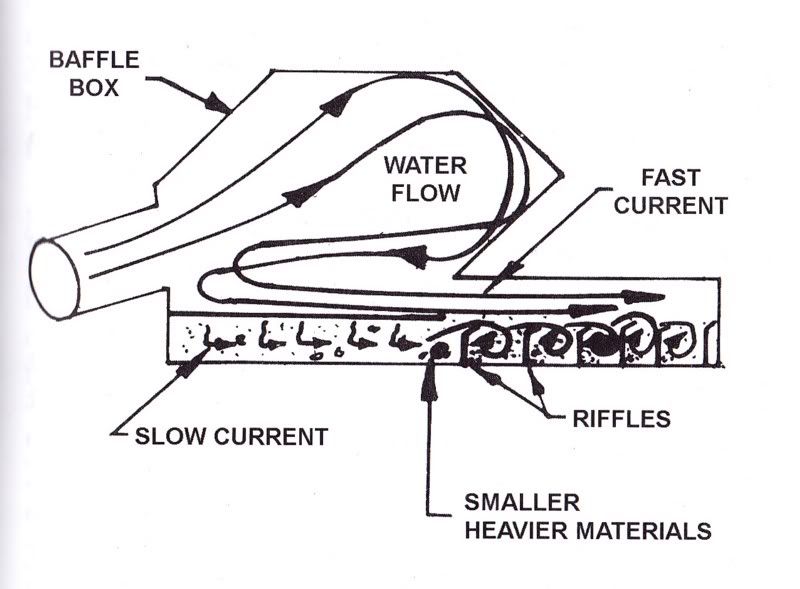

Another thing with the side entry pressure hose is that as material is moving & coming up the suction hose the material is seperating & sorting itself as to its specific grafity, ie the heavies, gold & black sands are draging behind the lighter material & falling to the bottom of the suction hose as it moves its way up from the stream bed towards the power jet & on to the sluice box. Guess what happens when that pre-sorted material passes over the power jet pressure hose inlet that is coming in on that angle???..... it blasts all that pre-sorted material in the suction hose all over the place & remixes it all up again just prior to the material hitting the sluice box. Not only that but with the old crasher boil baffle box style header box of earlier dredges, that did the exact same thing only a lot worse as you can see in the below diagram.

Why waste all that effort of the material naturally sorting itself as it is coming up the suction hose?? That has been some what improved with todays flare entry into the sluice box, replacing the old crasher type box entry. The only benefit of a crasher type header box is if you are dealing with clayey, sticky, puggy type material. The crasher/boil box will slam the material into the back wall of the box, thus helping to shatter the material, plus the boiling stirring action inside the box will further help in breaking up this type of material.

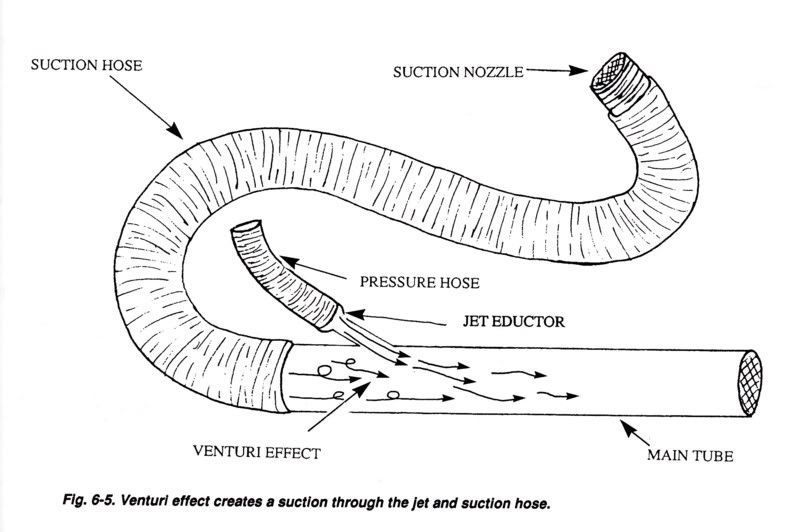

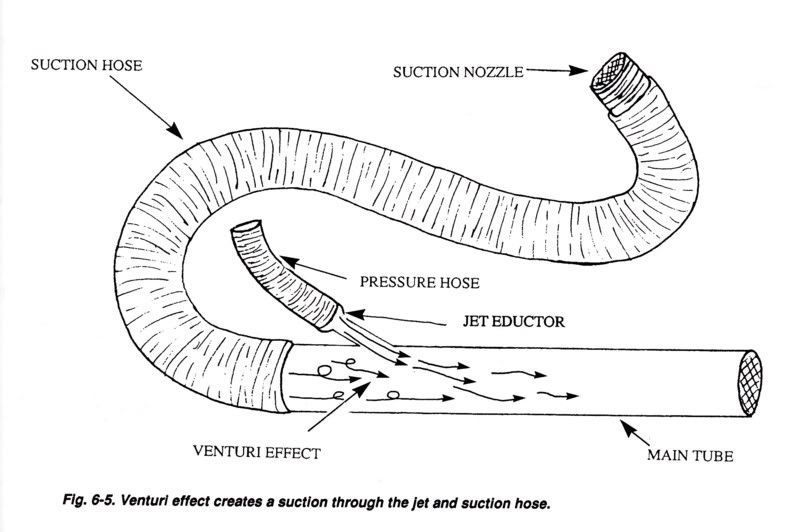

Getting back to the jetting systems of dredges: ie, power jets & suction nozzles.

These are what create the suction of a dredge venturi system & no material is sucked through the pump itself. Imagine the damage to a pump if this were the case.... A volume of water under pressure is pumped into a steel tube at an angle as shown in the above diagram. This causes a vacuum effect, venturi effect, just behind where the water enters the main power jet tube, which in the case of a suction nozzle being at the start of the suction hose, pushers the material up the hose. Where as with a power jet being usually at the end of the suction hose & just prior to entering the sluice box, pulls the material up the suction hose.

The jet system is the most important component of a suction dredge. The idea is to get the highest pressure & greatest volume that is attainable from a pump & utilise it to its most effectiveness to get the most suction power at the suction hose entry.. This is done by reducing the size of the jet eductor just prior to it entering the main jet tube, be it a power jet or a suction nozzle. Here we have a 4" suction nozzle. You will see how the pressure pipe inlet in to the suction nozzle at the elbow bend enters to blast the water pressure down the centre of the main pipe & so being quite efficient due to no bouncing off the side wall & less friction losse.

Here we have a pic looking down inside the nozzle were you can see the reduced size of the eductor. The pressure hose from the pump to the nozzle is 1.5 inch & reduces at this point to about 3/4 of an inch to ramp up the pressure a lot more to create the venturi effect in the nozzle. It is also at this point that a trash pump, which is designed for water volume, will cavitate & choke as they arent designed for pressure. Where as a pump designed for a dredge is volume & pressure. Big difference.

Close up

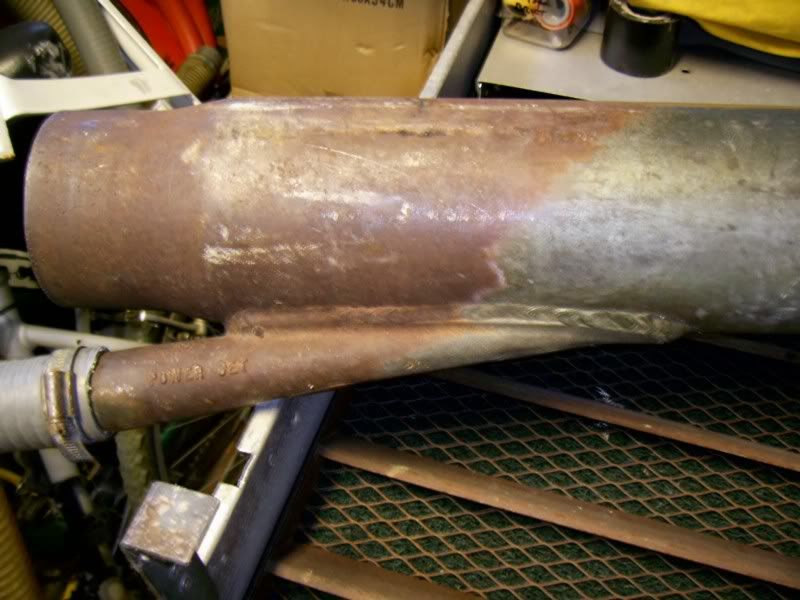

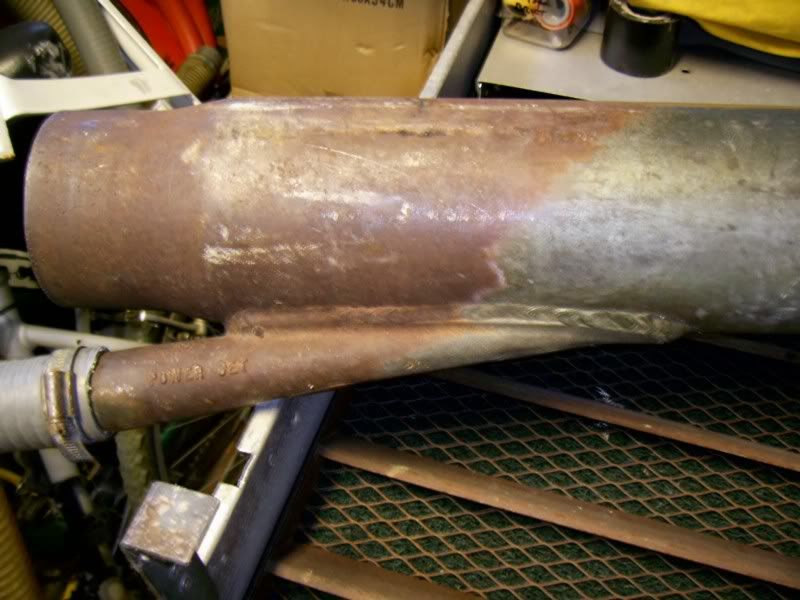

Here we have a 4" power jet.

You will notice the inlet of the pressure pipe inlet coming in from the side & the angle it is entering at. This pic is taken looking up the the power jet from the entry end of the suction hose & towards its discahrge into the sluice box.

And this is looking back down the oppostie way & you can see the pressur inlet.

The highest volume & highest pressure mixture is hard to get right without trial & error on the part of the dredge builder & why most dredgers buy their equipment instead of building their own. Different pumps have different pressure & volume capacities which require different size power jet eductor reductions.

These changes also effect how wide & long a sluice box needs to be in order to accomodate & coupe with the amount of water being pumped down & through the box. So as you can see it is all a bit of a science to get all the right mixes to have an efficient set up from motor/pump through to your suction system & sluice box /gold saving ability.

Happy hunting

JW :)